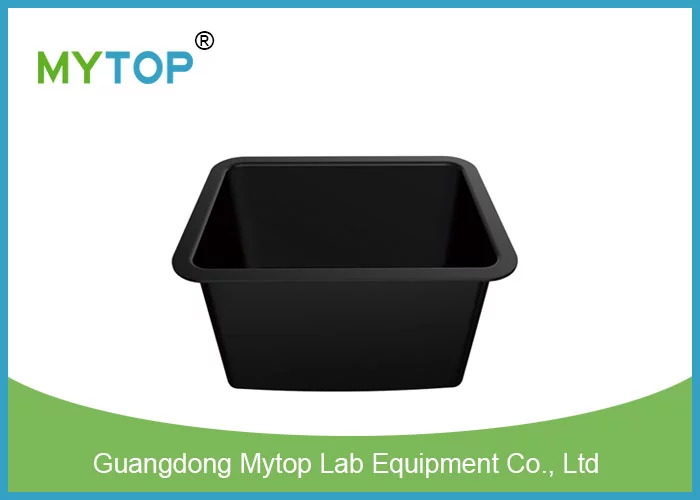

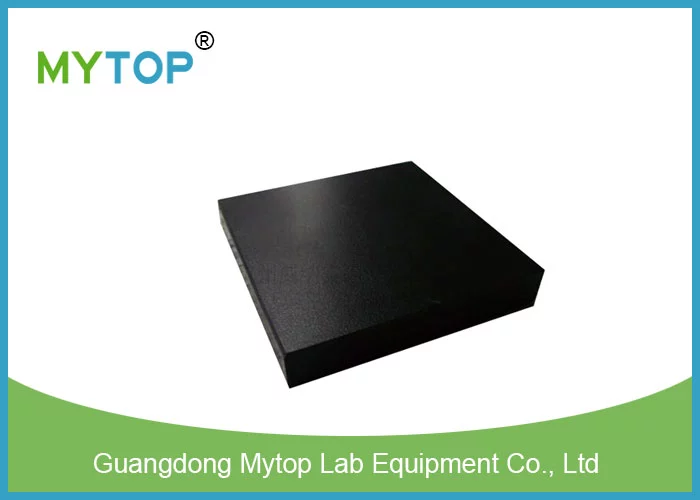

Phenolic Resin Worktop

Features:

1. Phenolic resin worktop is economy for chemical labs with good chemical resistance

2. Phenolic resin worktop is flatter and more stable in color than epoxy resin worktop

3. The after processing is the easiest and contractors can do small changes at the installation site

1. Phenolic Resin Worktop Material

Phenoic resin worktop is mainly made from quality mutiple=layer kraft payer, phenolic resin, and balance papar on both sides. Processed by being laminated by a special chemical resistance film on the surface, our phenolic resin worktop performs excellently on SEFA testing

2. Phenolic Resin Worktop Size

| Model | Size | Regular Color |

|---|---|---|

| MT-PRW-2440 | W2440*D1220*T12.7/16/19/25 mm | Black, Grey, Color Customized For Big Order |

| MT-PRW-3000 | W3000*D1500*T12.7/16/19/25 mm | Black, Grey, Color Customized For Big Order |

| MT-PRW-3600 | W3600*D1500*T12.7/16/19/25 mm | Black, Grey, Color Customized For Big Order |

Method A

For volatile chemicals – A cotton ball, saturated with the test chemical, was placed in a one ounce bottle (10mm x 7mmtest tube or similar container). The container was inverted on the test material surface for a period of 24 hours.Temperature of test: 23° +/- 2°C (73° +/- 4°F). Thi s methodwas used for the organic solvents..

Method B

For non-volatile chemical – Five drop of the test chemical

were placed on the test material surface. The chemical was

covered with a watch glass for a period of 24hours.

Temperature of test: 23° +/- 2°C (73° +/- 4°F) This method

was used for chemicals listed below other than solvent.

Rating :

0 No detectable change in the material

Level 1 Slight detectable change in color or gloss but no change in function or life of the surface

Level 2 A clearly discernible change in color or gloss but no significant impairment of surface life or function

Level 3 Objectionable change in appearance due to discoloration or etch, possibly resulting in deterioration of function over an extended period time

| Test No. | Chemical | Method | Rating | Comments |

|---|---|---|---|---|

| 1 | Acetate,Amyl | A | 0 | / |

| 2 | Acetate,Ethyl | A | 0 | / |

| 3 | AceticAcid, 98% | B | 0 | / |

| 4 | Acetone | A | 0 | / |

| 5 | Acid Dichromate,5% | B | 0 | / |

| 6 | Alcohol,Butyl | A | 0 | / |

| 7 | Alcohol,Ethyl | A | 0 | / |

| 8 | Alcohol,Methyl | A | 0 | / |

| 9 | Ammonium Hydroxide,28% | B | 0 | / |

| 10 | Benzene | A | 0 | / |

| 11 | Carbon Tetrachloride | A | 0 | / |

| 12 | Chloroform | A | 0 | / |

| 13 | Chromic Acid,60% | B | 0 | / |

| 14 | Cresol | A | 0 | / |

| 15 | Dichloroacetic Acid | A | 0 | / |

| 16 | Dimethylformanide | A | 0 | / |

| 17 | Dioxane | A | 0 | / |

| 18 | Ethyl Ether | A | 0 | / |

| 19 | Formaldehyde,37% | A | 0 | / |

| 20 | Formic Acid,90% | B | 0 | / |

| 21 | Furfural | A | 0 | / |

| 22 | Gasoline | A | 0 | / |

| 23 | Hydrochloric Acid,37% | B | 0 | / |

| 24 | Hydrofluoric Acid,48% | B | 0 | / |

| 25 | Hydrogen Peroxide,30% | B | 0 | / |

| 26 | Iodine,Tincture | B | 0 | / |

| 27 | MethylEthyl Ketone | A | 0 | / |

| 28 | Methylene Chloride | A | 0 | / |

| 29 | Mono Chlorobenzene | A | 0 | / |

| 30 | Naphthalene | A | 0 | / |

| 31 | Nitric Acid,20% | B | 0 | / |

| 32 | Nitric Acid,30% | B | 0 | / |

| 33 | Nitric Acid,70% | B | 0 | / |

| 34 | Pheno,90% | A | 0 | / |

| 35 | Phosphoric Acid,85% | B | 0 | / |

| 36 | Silver Nitrate, Saturated | B | 0 | / |

| 37 | Sodium Hydroxide, | B | 0 | / |

| 38 | Sodium Hydroxide,20% | B | 0 | / |

| 39 | Sodium Hydroxide, | B | 0 | / |

| 40 | Sodium Hydroxide, | B | 0 | / |

| 41 | Sodium Sulfide, | B | 0 | / |

| 42 | Sulfuric Acid,33% | B | 0 | / |

| 43 | Sulfuric Acid,77% | B | 0 | / |

| 44 | Sulfuric Acid,96% | B | 0 | / |

| 45 | Sulfuric Acid,77% | B | 0 | / |

| 46 | Toluene | A | 0 | / |

| 47 | Trichloroethylene | A | 0 | / |

| 48 | Xylene | A | 0 | / |

| 49 | Zinc Chloride, | B | 0 | / |