Food Lab Solution

Food laboratory is a laboratory where food, food additives and food-related products are the testing objects. According to the design and construction requirements of laboratory buildings, food testing laboratories can be divided into general laboratories and special laboratories

The laboratory should be reasonably divided into relatively independent areas in order to realize the overall function and achieve the basic requirements of safety, rationality, science, convenience and energy saving. According to actual needs, it is generally divided into the following three parts: bacteria laboratory, physical and chemical laboratory, and office.

Bacteria laboratory includes ① Bacteria inspection operation room; ② Sterile room; ③ Culture medium production room; ④ Washing and disinfection room.

The physical and chemical analysis laboratory (or combined with the bacteria inspection operation room) includes ①The physical and chemical analysis room (also serves as a sensory laboratory) ②Instrument room (also contains a small number of instruments such as a bacteria room microscope).

1. Bacteria inspection operation room (routine operation): The bacteria inspection operation room is the main operation room for bacterial culture and inspection, and the main facility is the laboratory bench. Requirements for the test bench:

(1) The area of the experimental platform is generally not less than 2.4×1.3m.

(2) The experimental platform should be in the center of the laboratory with sufficient light; it can also be used as a side platform.

(3) Small basins and faucets are installed on both sides of the test bench.

(4) A reagent rack is set in the middle of the laboratory bench, and the rack is equipped with fluorescent lamps and sockets.

(5) The materials of the test bench should be heat resistant, acid and alkali resistant.

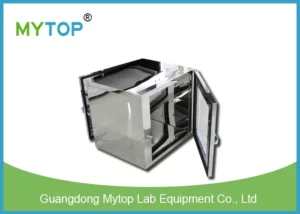

2. Cleanroom: The cleanroom provides a relatively sterile working environment for microbiological experiments through air purification and space disinfection. The sterile room is the main working room for sample processing and inoculation and culture and should be close to the bacteria inspection operation room Connected. In order to meet the aseptic requirements of the sterile room, the sterile room should meet the following layout:

(1) The entrance is kept away from the corridor and located in the bacteria inspection operation room.

(2) It is separated from the operation room by two buffers.

(3) UV lamps are installed in the sterile room and buffer room, and it is required to install a 30W UV lamp every 3 square meters.

(4) The center of the experimental platform is set in the sterile room (both the experimental platform and the side platform), and the distance between the ultraviolet lamp and the experimental platform should be less than 1.5m.

(5) There are double windows between the sterile room and the operating room to form a small passage.

3. Culture medium production room: The culture medium room is a place where the culture medium and test reagents required for microbial culture are produced and prepared. The main equipment should be side tables and medicine cabinets.

(1) An electric furnace should be placed on the side table to meet the requirements of melting and boiling the medium.

(2) The side table material should be resistant to high heat, acid and alkali.

(3) The medicine cabinet stores some general medicines and reagents in different categories.

(4) Dangerous, perishable, flammable, toxic and harmful drugs are stored in a separate safe.

(5) Place a balance on the side table for weighing medicines.

4. Washing and disinfecting room: The washing and disinfecting room is used to disinfect and wash ready-to-use and used glassware, culture medium and dirt, and its area should be greater than 10m2. In order to meet the function of washing and disinfection, the washing and disinfection room should be equipped with:

(1) 1-2 sinks, the upper and lower water network of the sink should be unblocked.

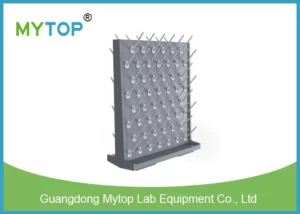

(2) Utensil cabinet or laboratory bench to place washed utensils.

(3) The power supply used for the autoclave should meet the electrical load.

(4) There are ventilation devices (ventilation hoods) or ventilation fans in the room.

(5) The qualified unit can also install a distilled water device for daily inspection in this room.